Under the Big Four blueprint, the Government wants to provide at least 500,000 affordable housing units by 2022.

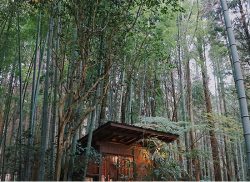

It is beautiful and sustainable. It is an energy saver, has zero emissions and is environmentally friendly. Its potential in architecture is immense. With its abundance, fast growth, hardy nature and resistance to water and bending, bamboo can be used in roofing, as well as in floors and furniture.

The reconstituted wood product, known as scrimber, has been used in China and Japan in landscaping and making outdoor furniture. The composite has several advantages, including low water absorption, high dimensional stability, and durability. Studies have shown that when bamboo is used with reinforced concrete, the combination can increase a building’s resistance to earthquakes.

Bamboo could thus play a critical role in Kenya’s development. As part of the Vision 2030, which seeks to transform Kenya into a middle-income country, the Government of President Uhuru Kenyatta, at the beginning of its second term, outlined the Big Four Agenda.

Under the Big Four blueprint (which includes manufacturing, affordable healthcare and food security), the Government wants to provide at least 500,000 affordable housing units by 2022.

This is intended to address the needs of the burgeoning population, with the State Department of Housing and Urban Development putting the deficit at 2 million units and an annual growth rate of about 200,000 houses.

The Government hopes the average price of houses will fall by up to 70 percent per unit, driven by development of infrastructure, utilities, proper designs, and cheaper building technologies.

The Government has noted that building materials account for at least 60 percent of the total construction costs. This could be reduced by up to 30 percent by using affordable, sustainable, locally available materials.

KBRC’s concept of appropriate technologies

To facilitate the success of the affordable housing programme, the Kenya Building Research Centre (KBRC), whose mandate is to find cheaper, sustainable building options, highlights the importance of incorporating science and indigenous technologies.

KBRC says the concept of Appropriate Building Materials and Technologies (ABMT), whose role is anchored in Sessional Paper No. 3 of 2004 on the National Housing Policy, provides for research and development of materials that are appropriate for local communities in terms of affordability, quality and ease of application, among other factors.

Widely regarded as a sustainable building material, the plant’s qualities could spur growth and development of the construction industry, which is key in building affordable housing

Along with developing such materials, the Government also projected to create about 300,000 new jobs in the construction industry, increase the sector’s contribution to GDP by 100 percent and reduce the low-income housing gap by 60 percent.

Emergence of the coronavirus pandemic in late 2019 has complicated efforts to build affordable housing by diverting much of the Government’s attention to controlling the disease, but officials remain upbeat about the programme.

Achieving the objectives of the programme depend, not only on making building materials easily accessible, but also on deploying inexpensive and sustainable technologies.

A perennial hardy grass, bamboo is both a woody and a herbaceous plant, often categorised as a non-wood or non-timber forest product. It is among the fastest-growing woody plants in the world. Widely regarded as a sustainable building material, the plant’s qualities could spur growth and development of the construction industry, which is key in building affordable housing. This giant grass is classified into more than 75 genera, with more than 1,200 species growing across the world.

A multi-purpose plant known to have at least 2,000 uses globally, at least 10 of its species are largely effective for use in the construction industry.

The culm, the bamboo plant’s trunk, is the part mostly used in construction, even though the leaves can also be used, especially in roofing.

500,000: Affordable housing units that the Government intends to build under the big four blueprint (which includes manufacturing, affordable healthcare and food security) by 2022

In eastern Africa, the most widespread species of the plant is Oldeania alpina (Yushania alpine), commonly called the highland bamboo. It is a native species found in Kenya, naturally occurring on Mt Elgon, Mt Kenya, Cherangany Hills, the Aberdares and the Mau Complex, among other places where it is widespread, according to the Bamboo Association of Kenya. However, several other counties also have significant quantities of the variety, though not on a large scale.

There are, nonetheless, other species common in Kenya, including the usually variegated Bambusa vulgaris, an exotic species from Asia, mainly used for ornamental purposes and landscaping.

Kenya is endowed with thousands of acres of bamboo. The country is therefore in a good position to enhance production and consumption of the plant, especially for building and construction. In the construction industry, bamboo is used – either on its own or with other materials – in many parts of the world, especially in China, Bangladesh, Indonesia and Burma.

22% – Amount of protein present in Bamboo foliage making it great feed for livestock and providing plenty of nitrogen when used as complementary to regular animal feed

Bamboo matures in three to four years and can be harvested for up to 80-120 years – which is a bonus for an industry that requires sustained availability of raw materials. Other trees take longer to mature.

80-120: Years bamboo can be harvested, which is a bonus for an industry that requires sustained availability of raw materials. Other trees take longer to mature. The plant itself matures in three to four years. Bamboo has considerably strong fibre, and a compressive strength that is twice greater than concrete

The global demand for wood continues to surge amid declining forest cover and urbanisation, thus the need for more housing and accommodation. In this context, bamboo provides an alternative to conventional wood, given that it is able to yield about 17 tonnes of material per acre in a well-managed plantation.

How handy is bamboo in building and construction sector?

The plant’s versatile nature portends many benefits to the sector. Bamboo has considerably strong fibre, a compressive strength that is twice greater than concrete, a high tensile strength and a shear stress that is higher than that of conventional wood.

It also has a wider span than conventional wood and can be curved without breaking, according to a 2015 study on its potential as a building material. Bamboo can be used in virtually any part of a structure.

In their 2009 study, “Classification of bamboo construction”, structural experts Widyowijatnoko Andry and Martin Trautz classified modern bamboo construction into conventional and substitutive models, which entail using its whole culms for erecting columns, although with a few modifications, and to replace other materials.

Because of its light weight, high elasticity and great resistance to breakage, bamboo is ideal for several construction purposes. It is considered a safer option for buildings in regions that are prone to tremors and earthquakes.

Bamboo is also cheaper than other materials, including conventional wood, steel and concrete, but still remains robust and durable when well treated before being used. Structurally, this versatile plant can be used as columns, beams, roof trusses and for scaffolding. Engineered bamboo can be used for roofing, because it is designed to function like conventional timber; the leaves can be used as thatch; and split pieces can be used as tiles, where the culms are cut at the nodes and then split into halves similar to round ceramic ridge caps and laid on a roof in an alternating upward and downward-facing pattern.

For walls, the versatility of bamboo means it can be used in the form of split culms, engineered and flattened pieces, and even as whole culms. Different parts of the plant can be used for windows, floor tiling, ceiling, doors and even curtains.

Bamboo cultivation

According to the Kenya Forestry Research Institute’s (KEFRI) guidelines for bamboo cultivation, it can be farmed in homesteads and commercial plantations, agroforestry, and in conservation programmes. The plant can be grown through seed propagation, using multiple node culm cuttings, wildings, offsets, tissue culture plantlets, as well as vegetative transfers.

When planting bamboo, it is important to plan the field layout for ease of harvesting and hauling of culms. After preparation of the site, the planting spots are dug at a spacing suitable for the specific species, in accordance with the plantation layout and design. The size of the holes depends on the planting material and climatic conditions. Larger and deeper holes are always better and allow for easier establishment of new plants. The seedlings should ideally be planted at the onset of the rainy season to ensure good survival. Weeding, mulching and replanting should be observed in cultivation of the grass.

When harvesting, the culms on the periphery of the bamboo should not be cut. Cutting should ideally be restricted to the oldest culms at the centre. Dead and dry culms should also be removed. Other than for building and construction, bamboo also comes in handy in the making of important household products.

Furniture, kitchen utensils, fencing materials, handicraft, and biofuel can also be made from bamboo. In Vietnam, architects use bamboo to build low-cost prefab houses mainly to address the shelter deficit in the Mekong Delta. Haiti, Costa Rica, Ecuador, El Salvador, Colombia, Mexico, Nepal, and Hong Kong, among other countries, have adopted bamboo in their building and construction industries. China, India, Japan, Myanmar, Thailand, Bangladesh, Cambodia, Laos, Malaysia, Indonesia, and the Philippines have also made significant investment in bamboo for their construction sectors.

Challenges and remedy

According to the Bamboo Association of Kenya, about 20 million hectares are under bamboo globally, with China accounting for 30 percent. In Kenya, the plant covers 140,000 hectares at altitudes ranging from 2,400m to 3,400m above sea level. KEFRI has been importing bamboo planting material to ensure its cultivation is enhanced.

However, lack of comprehensive awareness of the plant’s potential and good technologies for processing it, as well as inadequate knowledge on handling, managing and harvesting bamboo, limit its use.

Due to its susceptibility to decay and attack by fungi and insects, especially powder post beetles, it is important to ensure the safety of bamboo after harvest. Such attacks often give bamboo low natural durability, hence, preservation methods are key to extending its durability. The processing and construction methods may also minimise attacks by fungi and insects.

Preservation could be through non-chemical methods such as curing, whitewashing, smoking, soaking in water, plastering, and constructing the structures on an elevated base such as concrete blocks, to reduce the chances of rotting when in contact with soil. Chemical preservation methods include sap displacement, fumigation, open tank and butt treatment.

Bamboo for construction, or for value-added products, should be stored in an elevated and covered area to protect and retain the quality. Because it is prone to invasion by pests and diseases, bamboo requires treatment before use.

36 Millions of hectares covered by bamboo worldwide, or an average of 3.2 per cent of the total forest area in 22 countries if bamboo outside forest land is included.

Its combustible nature is also a downside. Still, the potential of bamboo in green construction is undeniable, and Kenya needs to adopt appropriate technologies, especially from Asian countries where it is widely used.

The National Bamboo Policy (2019) calls for a strategy to promote the plant’s cultivation and commercialisation at the national level. Such promotion could enhance bamboo’s adoption, hence, boosting the construction industry.

With global warming and calls for sustainable exploitation of the planet’s resources, bamboo is emerging as one of the most sustainable options in construction, as deforestation has cut the supply of what is considered high-quality wood.

And while adoption of bamboo in construction in Kenya is limited, efforts are underway to influence people’s perceptions. In 2009, demo houses were put up by the International Network for Bamboo and Rattan (INBAR) at Maseno University, Kenya, to showcase to local people various uses of bamboo from their farms.

Bamboo totals more than 36 million hectares worldwide or an average of 3.2 per cent of the total forest area in 22 countries if bamboo outside forest land is included. Sixteen countries in Asia together have a total of close to 24 million hectares of bamboo forest, while a total of over 2.7 million hectares of bamboo forest are found six African countries (Ethiopia, Kenya, Nigeria, Uganda, the United Republic of Tanzania and Zimbabwe). In Latin America, at least 10 countries have significant bamboo resources. A total of over 10 million hectares is considered a realistic estimate for the region – Source: Food and Agricultural Organisation (FAO).